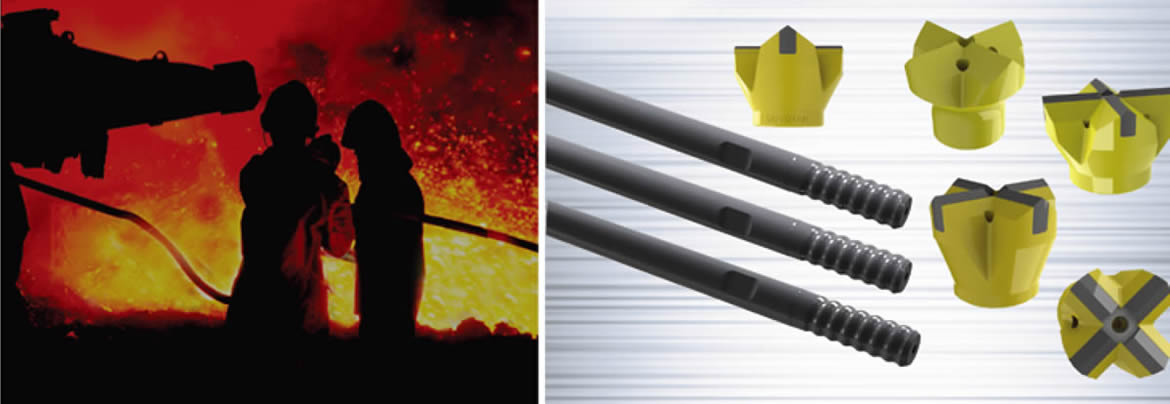

A common situation of H22 drill wear

Drill rod is definitely the most commonly used in mining equipment, even is one of the indispensable equipment. In H22 drill rod, for example, whether in the mines to find that, still in coal mining, are subject to different degree of wear and tear, it is also a lot of customers care about. So how can prolong the service life of drill rod? First must know H22 drill wear and tear of the common case. Partial play phenomenon In use process, if some parts appear aging or wear and tear, will make the new H22 drill rod can't work in the position of accurate, led to the uneven hit parts of the stress, produce certain partial situation, long-term operation may affect the service life of the machine. Recommend regular inspection to avoid this situation. The fracture phenomenon After heat treatment, there will be a certain H22 drill rod crack situation, this kind of situation will tend to be limited to the material quality, generally split crack and tidy, like cutting. There is material inside have bad points, small cracks may cause the naked eye is difficult to find. Empty play phenomenon Empty a problem is a common problem in the operation, often because of operation not skilled or inattention and lead to all sorts of problems, operating on the defects. Often the personnel training to related people, technically can be completely avoided. In addition, common and mushroom H22 drill rod and drill rod bending, split evenly, and so on, are generally and the material of the product itself has a lot to do, suggest the consumers at the time of purchase from the above several aspects of the measure, pay more attention to in the process of use, including strictly abide by the operation specification.

Xihu Town, Yanggu County, Shandong Province, P.R.China 252311

Tel:0635-6366658 / Fax:0635-6319568 / Email: service@atlasrocktool.com / www.atlasrocktool.com